Revolutionize Your Planting Solutions with Blow Molded Planter Pots

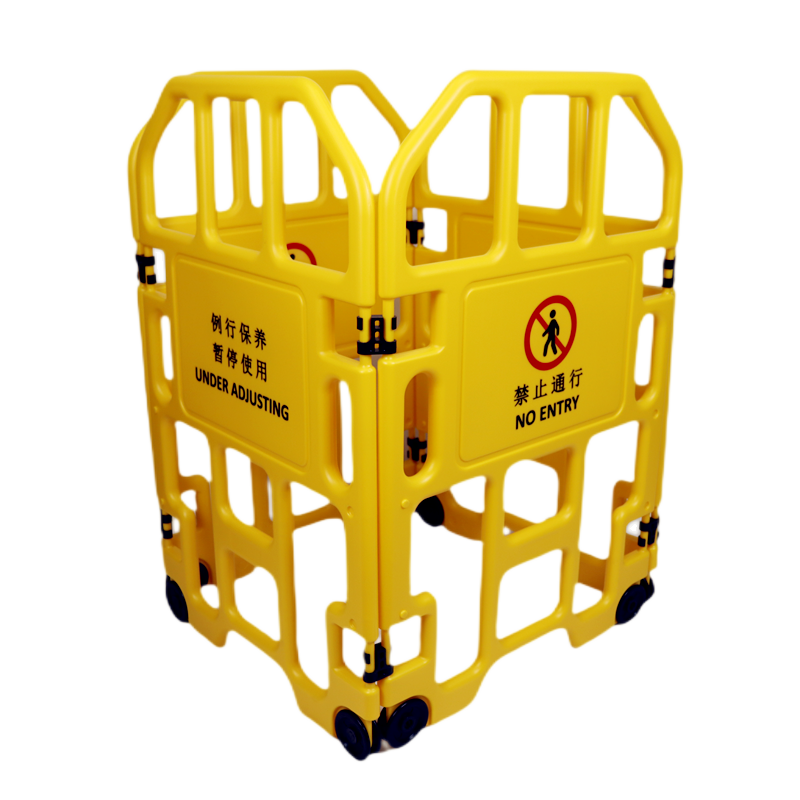

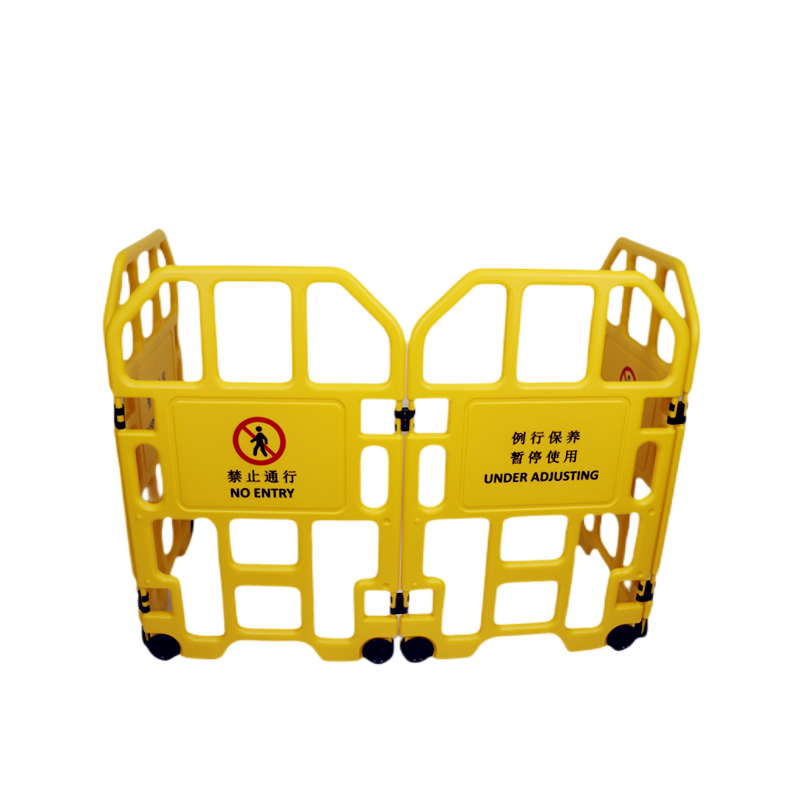

Plastic fence, also known as plastic enclosure, is divided into a fence body and support legs, which can hold water or sand.

Scope of use: It can be widely used in property management, road construction sites, sidewalks, road isolation, urban transportation arteries, highway ticket gates, toll stations and other places that require isolation.

Raw material

Plastic fences are made of PE plastic blown or injection molded, integrating the toughness of plastic into one. They not only have good flexibility, but also have super strong collision resistance. The reflective material adopts crystal colored grids.

(1) In terms of structure, the fence body adopts interconnected connection devices, breaking the traditional limitations of using connectors, making it more convenient to connect. When applied to traffic accident handling and road construction, it will also effectively shorten the layout time of traffic facilities, improve road isolation and traffic diversion efficiency.

(2) The fence body is covered with crystal colored grid reflective material, which has a significant reflective effect at night, has a clear warning effect on drivers, and can reduce the degree of casualties in accidents, forming a safer protection and effectively reducing traffic accidents and losses of vehicles.

(3) High antioxidant capacity, less prone to aging and becoming brittle, with a bright and bright color.

(4) Impact resistant, water resistant, oil resistant, and dust resistant. Paired with crystal colored grids as reflective materials, it improves the effectiveness of alarm and isolation.

Specification: length 1567X width 80X height 1000mm [1]

Specification of column body: 1567L x 56W x 835mm H

Support foot specification: length 430X width 80X height 225mm

Body material: PE plastic

Weight: 4kg

Counterweight weight: Sand loading: 6.5kg; Water loading: 3kg

Body color: black, red, blue

1. When installing the product, it is important to avoid dragging or falling as much as possible to avoid reducing the product's lifespan and appearance.

2. The outlet surface of the product drainage outlet should face towards the construction site as much as possible to prevent theft.

3. When injecting water, the pressure of the water pipe should be increased to accelerate the installation speed. After injecting water to the set water level hole surface, it is sufficient. Water can also be injected at intervals of one or several depending on the length of the construction period and the environmental conditions of the construction site, or the water level is lower than the set water level hole. This water injection method will not affect the stability of the product.

4. The waist of the product has been designed and pasted with national standard warning reflective film, and there is a flag insertion hole on the top of the product, which can be used for inserting colored flags or installing warning lights and warning devices. You can also drill holes in the product section to install lighting fixtures or use self tapping screws to fix and connect various objects. This small installation will not affect the quality and performance of the product.

5. For fences that have been torn, damaged, or leaked during use, the repair method is simple. It can be easily repaired with a 300W and 500W hot plastic strip gun, and can also be repaired with hot plastic.

6. Due to the use of top-notch imported pigments from the United States, the product has a bright color that can be used outdoors without fading for five years.

7. If the product is stuck with soil or dust during use, it can be washed clean when it rains. For thick soil, it can be rinsed with water. For oil stains such as adhesive paint and asphalt, various cleaning agents can be used to wipe and clean them, which will not damage or damage the surface smoothness of the product. But do not use sharp tools or knives to scrape, as this can easily damage and damage the surface smoothness of the product.

8. High density polyethylene materials have good reducibility, and for products that are deformed and bent throughout the board, as long as they are placed vertically and connected, they will quickly restore flatness. Therefore, for inventory products, flat cross stacking can be used to reduce the space for inventory product placement.